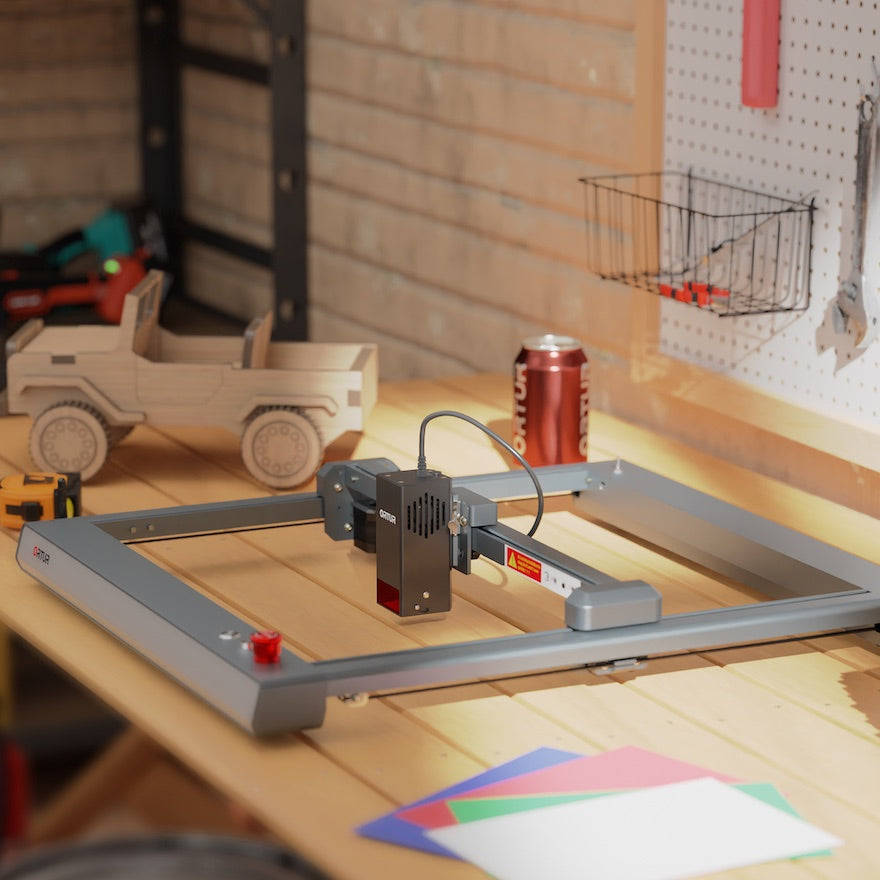

Ortur Laser Master 3 Review and Tests

Thanks to Mellowpine -John for sharing

This article is a detailed test and review of the Ortur Laser Master 3. John tested the OLM3 for engraving and cutting on several materials including plywood, wood, glass, aluminium, ceramics and acrylic. If you are interested in OLM3, don't miss this article!

Catalogue

- Testing Ortur Laser Master 3 on Different Materials

- Our Review and Verdict of Ortur Laser Master 3

Testing Ortur Laser Master 3 on Different Materials

I tested Ortur Laser Master 3 by engraving and cutting different materials. The results are given below.

| Material | Job Type | Speed | Power | No. of Passes | Air assist |

|---|---|---|---|---|---|

| Plywood | Engraving | 6,000 mm/min | 50% | 1 | off |

| Plywood | Engraving | 12,000 mm/min | 100% | 1 | off |

| 3mm Plywood | Cutting | 600 mm/min | 100% | 2 | 30 psi |

| 10mm Pine | Cutting | 100 mm/min | 100% | 2 | 30 psi |

| 10mm Pine | Cutting | 300 mm/min | 100% | 6 | 40 psi |

| Glass | Engraving | 1500 mm/min | 70% | 1 | off |

| Aluminum Card | Engraving | 5,000 mm/min | 100% | 1 | off |

| Ceramic Tile | Engraving | 3,000 mm/min | 100% | 1 | off |

| 2mm Black Acrylic | Cutting | 600 mm/min | 100% | 5 | 30 psi |

Engraving on Plywood

You can get good engravings on plywood at 50% power and 6,000 mm/min speed. If you want quick jobs, you can use 100% power at 12,000 mm/min for engraving on plywood.

The small module and low center of gravity design prevent vibrations at high speeds.

When you are engraving on wood or ply, do not use an air assist as it causes the smoke to spread out and stain the wood surface.

Cutting 3mm Plywood

When you are using a laser to cut plywood or wood, it is better to do it with an air assist.

Ortur Lasser Master 3 cut 3mm ply at 600 mm/min in 2 passes with a 30 psi air assist.

I got clean edges with fewer burn marks.

You will not get clean edges if you do not use an air assist.

Cutting 10mm Pine

I was able to cut 10 mm thick ply in about 2 passes going at 100 mm/min using a 30 psi air assist.

However, the laser didn’t cut through completely at places with hard grains.

To get a clean edge finish you need to run it at 300 mm/min and go for 6 passes to cut 10 mm pine. I used 40 psi air assist pressure.

Engraving Glass

I engraved a piece of glass after giving it a coat of black spray paint.

I used 70% power and engraved at 1500 mm/min.

The engraving turned out good, with no chipping, and had good contrast.

Engraving Painted Aluminum Business Cards

II was able to engrave on a painted aluminum business card to reveal the metal underneath.

After wiping it off with a clean cloth, the engraving had a good and shiny finish.

I did the engraving at 5,000 mm/min at 100% power.

Engraving White Ceramic Tile

I engraved an image on a white ceramic tile after coating it with white paint. The Ortur Laser Master 3 was able to engrave tile at 3,000 mm/min speed and 100% power.

I did the engraving with 0.1 mm line spacing, and it took me around 48 minutes to engrave a 6” x 4” photograph.

The image had good detailing except for some dark areas, and that is because I used the image directly without any editing to bring out the details.

Cutting 2mm Black Acrylic

I tried cutting 2mm thick black acrylic using the settings recommended by Ortur and was able to cut it at 100 mm/min in one pass with an air assist.

I tried some tests and figured out that you get the best edge finish when you cut it at 600 mm/min speed in 5-6 passes.

Using this setting also gives you a smaller kerf width.

Our Review and Verdict of Ortur Laser Master 3

Size and Build

The Ortur Laser Master 3 has an open-frame design with a dark gray color. It uses unique extrusions that are powder coated to provide a better finish. It has integrated most electronic components within the frame providing a futuristic design with minimal components.

The frames of the machine are of aluminum. Other components are made using steel, brass, plastic, etc., and have an overall weight of 14.33 lbs.

The machine offers a work area of 15.74" x 15.74" (400 x 400 mm), and the footprint measures 23.1" x 25.9" x 5.9" (588 x 660 x 150 mm).

The design is where the Ortur Laser Master 3 stands out amongst other lasers.

It has a sleek design with a low profile and concealed controller and wiring. The only thing that sticks out is the cable that runs from the controller to the laser.

Laser Module

The laser module on Ortur Laser Master 3 uses two 5.5W diode lasers to provide a combined output of 10W.

It is one of the smallest 10W laser modules out there and is smaller than some 5W modules. Interestingly Ortur has managed to fit two cooling fans inside the small module.

This means the lens and laser receive adequate cooling during long hours of operation.

Also, it uses a special lens setup to provide a compressed laser spot size of 0.05 x 0.1 mm and a focus depth of 0.8 mm.

The module also has a pull-down focus liver, all you need to do is, flip it down, lower the module till it touches the material, and flip it back up.

Ortur had made no changes here. The autofocus setup is similar to the 10W modules they use on their other machines. But it's better than using their old aluminum cylinder block.

Material Capability

The 10W laser module of Ortur Laser Master 3 is powerful enough to work on wood, paper, leather, plastic, foam, fabric, acrylic, anodized metal, stone, rubber, etc.

In addition, the lens's 8mm depth of field allows the laser beam to stay in focus for a longer distance, making it suitable for cutting jobs.

If you cut in multiple passes, you'll be able to cut up to 20mm thick workpieces. But cutting thicker materials with multiple passes causes dark char along the cut path that will require further processing.

The laser beam produced by the 10W laser module has a wavelength of 455±5nm. It's not very effective at working on reflective bare metal surfaces. But you'll be able to make decent engravings on painted or anodized metal surfaces.

Interestingly it can make good engravings on bare steel surfaces.

Also, by using the dynamic engraving mode on the software, you can work to make professional engravings with gradients. In dynamic engraving, the software automatically adjusts the laser's output power and speed based on the dark contrasts in the image.

Ortur has listed out laser settings (cut and engrave) for most materials on its website. It'll be a good starting point for any of your projects.

Keep in Touch with Ortur

@orturtech

@orturnet

@orturnet

Related Articles

First-class Cutter & Multi-material Engraver---Ortur Laser Master 3 20W

Laser Engraving 101: This is How to Engrave Metal like a Pro

Ortur Laser Master 3 LU3-20A Unpacking and Assembly

Related Articles

First-class Cutter & Multi-material Engraver---Ortur Laser Master 3 20W