Solved: Laser Engraver Y axis

Moves to which direction?

This article solves the trending search query of laser engraver engraver y axis moves to which direction, which seems to be hassling quite many DIYers out there.

- Axes of Laser Engraver

- Using the Y-axis in laser engraving

- Setting Up a Laser Engraver for Accurate Y-Axis Movement

- Conclusion

Axes of Laser Engraver

To get into the trending online query of “laser engraver engraver y axis moves to which direction” we will first visit the basics of this topic. Laser engraving uses laser beams (very obvious) to engrave or cut various materials in different patterns, and to do this, they use the universal two axes, X and Y. The X-axis shows horizontal movement, or from left to right. The Y-axis, on the other hand, is vertical, or from up and down, and vice versa. The z-axis works for focus rather than movement of the laser module.

Relative to the movement of the Y-axis, most laser engravers draw a positive Y-axis direction towards the rear of the laser cutter machine, while the negative Y-axis direction is towards the operator. However, this may not be the case for you and depends on how your machine is arranged as well as the software settings that you are running with the hardware.

To even better explain the trending query of “laser engraver engraver y axis moves to which direction," let's dive further: A positive Y-axis movement usually implies the movement of the laser module in what usually seems to be the opposite direction of the operator, that is, towards the rear part of the body of the machine. The negative Y-axis movement will be from the laser head to the operator, where the direction is opposite.

Using the Y-axis in laser engraving

As one would expect, both two axes hold a pivotal role in helping guide the laser module to function properly and can be configured in different ways in software like LightBurn or AI. When it comes to the Y-axis, the configurable speed, power, and accuracy of the movements in the Y-axis depend on the type of material and design complexity. To learn even better to explain the query “laser engraver engraver y axis moves to which direction,” consider this breakdown:

1. Speed: Slow y-axis speed is preferable in cases where a high level of engraving detail is required, while faster speed is desirable when quicker engraving is needed for less detailed work.

2. Power: These settings refer to how far the laser goes when engraving the material present on the machine’s bed. Higher power settings on both the X and Y axes can easily fuse softer materials.

3. Acceleration: Some special laser cutters also feature the option to configure these speeds. This option in their software enables the user to set the acceleration of the Y-axis, which assists in limiting the shock movement of modules. This gives smooth engraving curves and details in your design.

This feature is quite important when it comes to making complicated designs. For example, when executing multilevel laser cutting, a proper lateral movement of the machine along the Y-axis is needed to create the desired depth impression in the final execution of the design.

Setting Up a Laser Engraver for Accurate Y-axis Movement

Laser engravers from any OEM are usually set from a “home” position, which is usually situated on the lower left. The place where the laser module is located at the beginning of the contouring movement is referred to as the Y-axis home position, which determines how far the laser head travels vertically. Not adjusting the design orientation accordingly can cause the laser to engrave your design upside down. Always configure your design orientation relevant to this starting point in the software you are using.

Engraving problems, such as mirroring of the design along the Y-axis, can be attributed to incorrect settings on the software. We always recommend checking and modifying these in the design software, depending on the correct orientation. Also, check that your Y-axis stop is properly engaged so the laser head doesn’t move too far or too short in an engraving session.

Conclusion

Before we conclude our take on the trending query of “laser engraver engraver y axis moves to which direction,” we can state that design software optimized to solve orientation problems (mentioned above) greatly improves the DIY laser cutting experience.

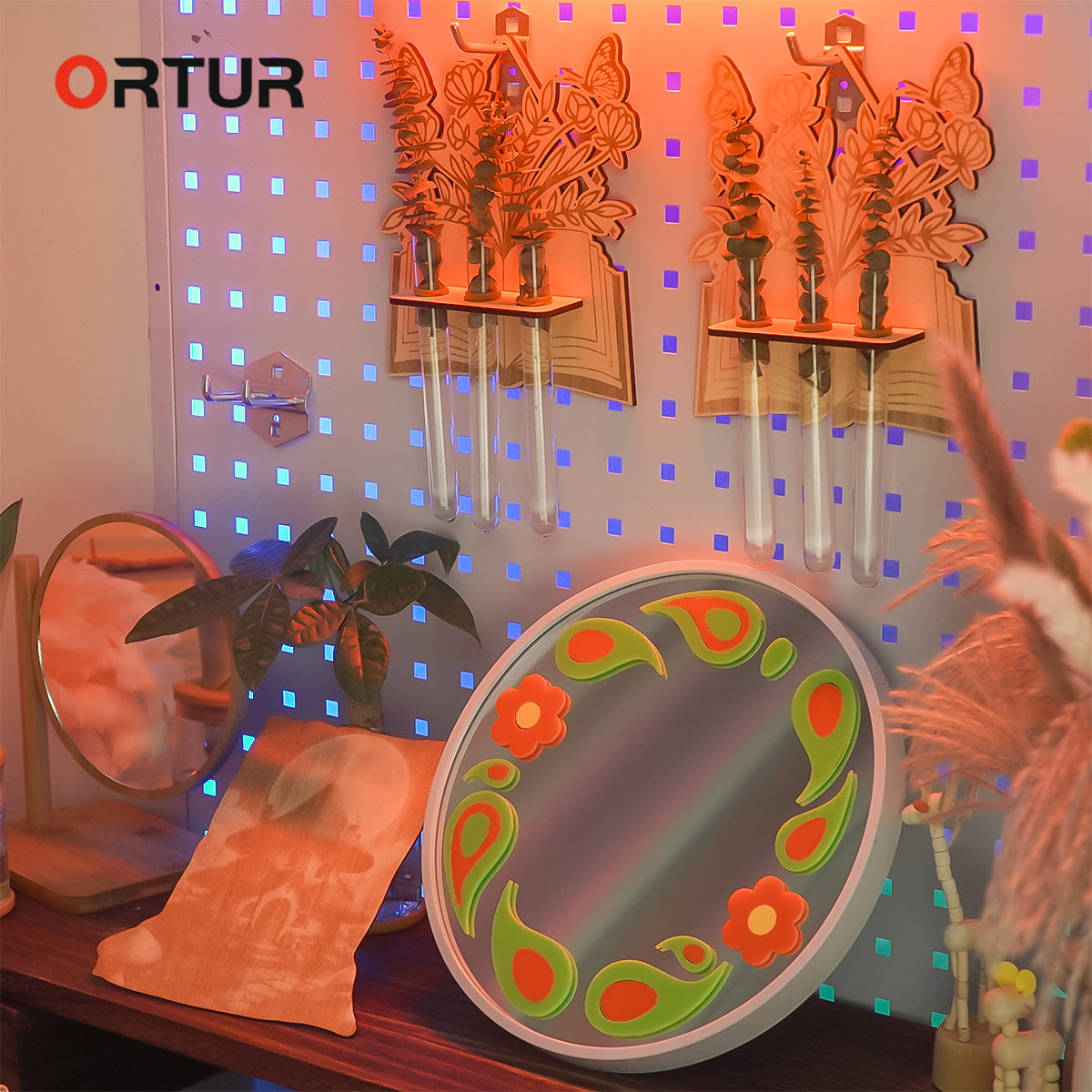

That is why we recommend using Inspiraesth, a complete laser cutting software that features an Ortur LM3 laser cutter and engraver. It offers a simple and professional mode selection for every engraving stage and has a user-friendly experience to correctly configure axes in one’s engraving design. The hardware itself is extremely efficient regarding the accuracy of final results thanks to its 0.01mm accuracy, next-generation motherboard, and impressive speeds of 20,000mm/min to do DIY things in a jiff.