Why Buy a Laser Engraver? From Basics to Compelling Reasons for Beginners

If you’ve ever wanted to add a personalized mark to a gift, transform home decor with your own hands, or dive into low-cost DIY projects, a laser engraver might be the tool that turns those ideas into reality. Before we dive into why it’s worth investing in one, let’s start with the fundamentals: What is a laser engraver? How does it work? This knowledge will lay the groundwork for your future understanding of "how to choose the right laser engraver" (such as ORTUR laser engravers), guiding you from "unfamiliarity" to "clarity" as you embark on your creative journey.

What is a Laser Engraver?

More Than Just a "Engraving Tool"— It’s a Creative Medium

Simply put, a laser engraver is a precision device that uses highly concentrated laser energy to engrave, cut, or mark materials. Unlike traditional hand tools (e.g., carving knives, electric drills) that require physical contact with the material, it modifies the material’s surface through non-contact "thermal action"—a feature that allows it to create fine details without damaging the material’s overall structure, making it suitable for far more scenarios than you might imagine.

Laser engravers have long transcended the limits of "professional tools" and now serve diverse needs:

For Home Users

Personalization Powerhouse

Engrave names on wooden keychains, engrave patterns on glass jars, or emboss designs on leather

For DIY Enthusiasts

Efficiency Booster

Complete complex patterns in minutes instead of spending hours on manual polishing

For Small-scale Creators

Side-hustle Tool

Make custom jewelry, holiday gifts, and other products to start a low-cost business easily

The "home diode laser engraver" we often mention (such as ORTUR’s mainstream models) is specifically designed for ordinary users: compact (about the size of a laptop), easy to use (plug-and-play right out of the box), and safety-compliant (meets FDA and CE certifications). No professional technical background is needed — beginners can get started quickly.

How does a Laser Engraver Work?

4 Steps to Understand "How Light Becomes a 3D Pattern"

Many people find "laser technology" complicated, but the working logic of a laser engraver is actually straightforward.

It revolves around four core steps: "energy generation → transmission → focusing → application." In simple terms, it’s like "painting on materials with a precise ‘light knife’".

Laser Generation — The "Source" of Energy

The core component of the machine is the "laser module" (e.g., Ortur Laser Modules). Taking the "diode laser" commonly used in home models as an example:

- The module is made of semiconductor materials such as silicon and gallium arsenide, with a "p-n junction" structure inside (p-type materials are positively charged, and n-type materials are negatively charged);

- When powered on and a voltage is applied, electrons in the n-type material move toward the p-type material and combine with "holes" (positively charged vacancies) in the p-type material. This process releases energy, which is emitted as a "laser beam"—this is how the laser "is born."

Laser Transmission — Guiding Light in the "Right Direction"

The generated laser beam does not act on the material directly. Instead, it is guided by "reflective mirrors" to ensure it travels in a straight line along a preset path, preventing beam deviation from affecting engraving precision. This process is similar to "reflecting sunlight with a mirror," except the reflective mirrors in laser engravers are precisely calibrated to ensure stable beam transmission.

Laser Focusing — "Concentrating" Energy

When the laser beam reaches the "focusing lens," it is compressed into an ultra-small "laser spot" (some ORTUR models can achieve a spot size as small as 0.03mm×0.03mm). Imagine this: the same amount of energy, concentrated into an area the size of a needle tip, becomes far more powerful — this is the key to the laser’s ability to "leave marks" on materials. The smaller the spot, the finer the engraving details.

Acting on Materials — Bringing Patterns to "Life"

When the focused laser beam touches the material’s surface, it reacts differently depending on the material’s properties, ultimately creating the desired engraving effect:

- Engraving: For non-metals like wood and leather, the laser slightly vaporizes or discolors the material’s surface to form grooves or textures (e.g., engraving text on wood);

- Marking: For materials like stainless steel and coated metals, the laser alters the material’s surface structure to leave a permanent mark (e.g., engraving a logo on a metal plate);

- Cutting: For thin materials like acrylic and cardboard, the laser’s energy penetrates the material and separates it along a preset path (e.g., cutting acrylic decorative pieces).

The entire process is precisely controlled by software (e.g., LaserGRBL, ORTUR’s dedicated APP) and a motor system. You only need to import a design file and set parameters — the machine will complete the engraving automatically without manual operation. This is the core reason why it’s "beginner-friendly."

5 Compelling Reasons to Buy a Laser Engraver: Practical for Daily Use and Long-term Goals

Now that you understand "what a laser engraver is" and "how it works," you might ask: "Is it really worth buying?"

The answer is yes — because it solves many practical needs. It’s not a "useless tool" but a "game-changer for enhancing daily life and creative efficiency".

No Professional Skills Needed — Start Your First Project in 10 Minutes

For beginners, "difficulty in getting started" is the biggest concern, but laser engravers eliminate this barrier completely

No Assembly Required

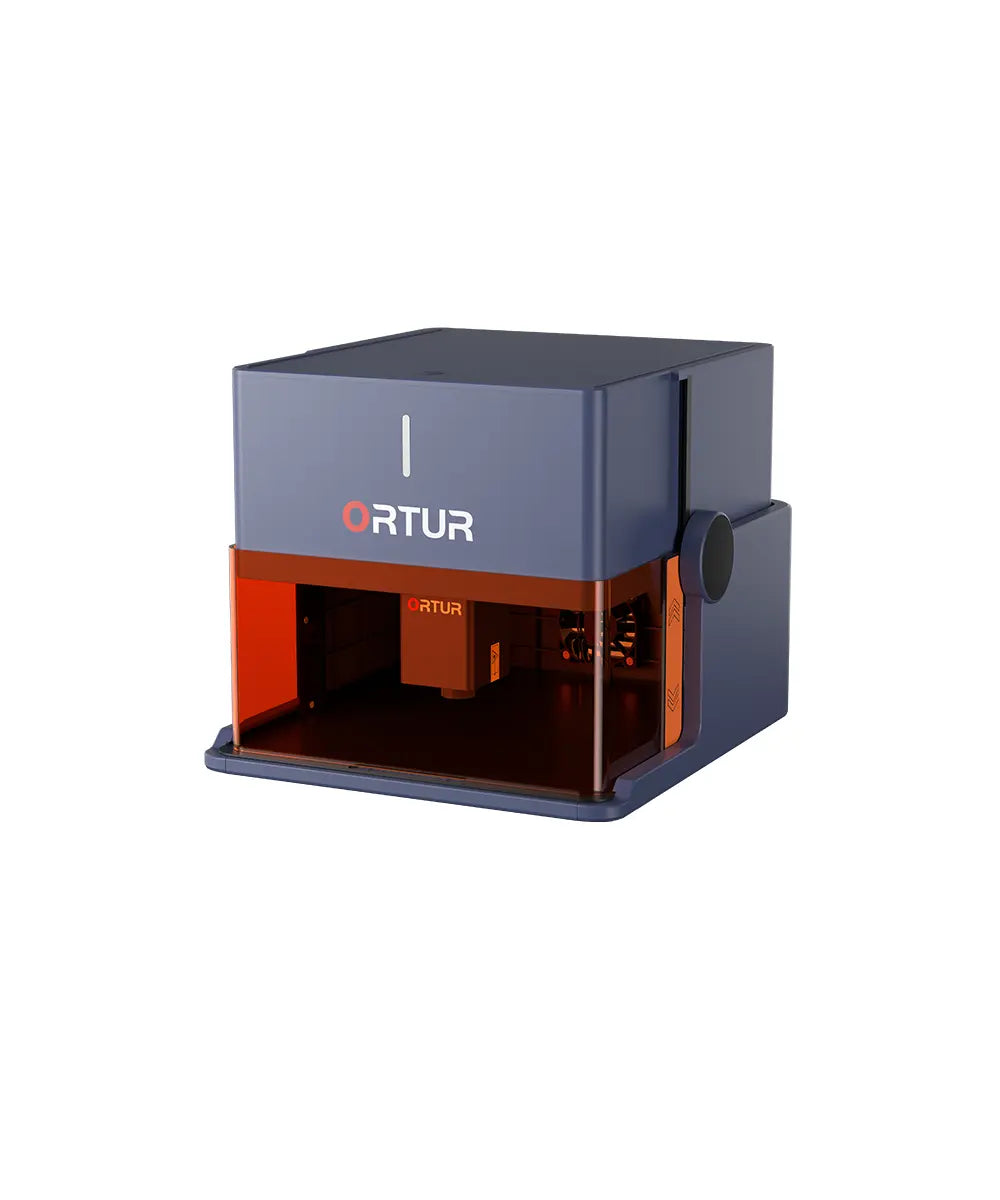

Portable models like the ORTUR R1 are ready to use right out of the box — just plug it in, no complex part assembly needed.

Simple Software

Equipped with multi-language operating software, it offers visual controls for importing designs and setting parameters. Even if you don’t know how to design, you can use built-in templates directly.

Quick Learning Curve

Complete a simple engraving (e.g., engraving letters on a wooden chip) in 10 minutes on your first try. The sense of accomplishment will keep you motivated, without the frustration of "finding it too hard.".

Multi-functional — Covers Countless Life Scenarios

Buying a laser engraver is like owning a "3-in-1 tool" (engraver + cutter + marker). It works with dozens of materials and adapts to daily life, holidays, and hobbies

Daily Use

Make personalized stationery (name-engraved notebooks), pet supplies (stainless steel ID tags), and home gadgets (wooden placemats).

Holidays

Create custom Christmas ornaments, Thanksgiving journals, and one-of-a-kind birthday gifts — hand-engraved items feel more thoughtful than generic store-bought products.

Hobbies

DIY handcraft models, custom notebook stickers, and upcycle old items (e.g., engraving patterns on an old wooden box) to make your hobbies more enjoyable.

Saves Time and Costs — Better Value Than Manual Work

Traditional hand carving is not only time-consuming but also prone to mistakes (a wrong cut can ruin the entire material). Laser engravers excel at both "efficiency" and "material conservation"

Complete simple patterns in seconds, and complex ones in about 30 minutes—over 10 times faster than manual work.

Precise laser control avoids material waste from errors. Small scraps (e.g., wood chips, acrylic offcuts) can even be used to make small pendants.

Making engraved items from raw materials costs over 50% less than buying custom-made products (e.g., a custom wooden ornament only costs $2–$3 in materials).

Safety-assured — Safe for Home Use

Many people worry: "Will the laser hurt my eyes?" However, regular home laser engravers (such as all ORTUR models) are equipped with comprehensive safety features

Compliance Certifications

Meet international safety standards like FDA, Class 1 and CE, ensuring laser radiation is safe for home use.

Hardware Protection

Built-in laser shields (block excess light), "stop-on-lid-open" function (automatically cuts laser when the lid is opened), and tilt power-off (shuts down immediately if the machine tips over) — even with children or pets at home, risks are avoided.

Operation Guidance

Safety precautions are clearly marked in the software and manual to guide proper use — no need to worry about misunderstanding complex instructions.

High Expandability — Meets Long-term Creative Needs

As you become more familiar with laser engraving, you can unlock more functions through "accessories," so the machine won’t become obsolete due to "single functionality"

Want to engrave mugs or bottles?

Add a Y-axis rotary chuck (e.g., ORTUR YRC1.0) to handle cylindrical objects and other irregular items.

Concerned about engraving fumes?

Pair it with a fume extractor (e.g., Ortur Enclosure 2.0 and Ortur Smoke Purifier 1.0) for cleaner indoor creation.

Want to engrave metal?

The LR4-2B 2W infrared laser module and LR4-1A 1.3W infrared laser module are specially designed for engraving metal and plastic.

Next Article Preview

How to Choose the Right Laser Engraver? Key Factors to Consider

Now that you understand the value of a laser engraver, the next key question is: "With so many models on the market, which one should I choose?" A good laser engraver isn’t just about "specs" — it needs to match your needs. For example, should beginners prioritize "no assembly" or "high power"? What laser modules are needed for different materials? How comprehensive is the accessory ecosystem?

In the next article, we will focus on "key factors for choosing a laser engraver" and use ORTUR models as examples to help you understand "why some models are more suitable for beginners" and "which designs improve the creative experience." If you want to find a "reliable, practical" laser engraver, the next article will give you a clear direction. Stay tuned!