Frequently Asked Questions

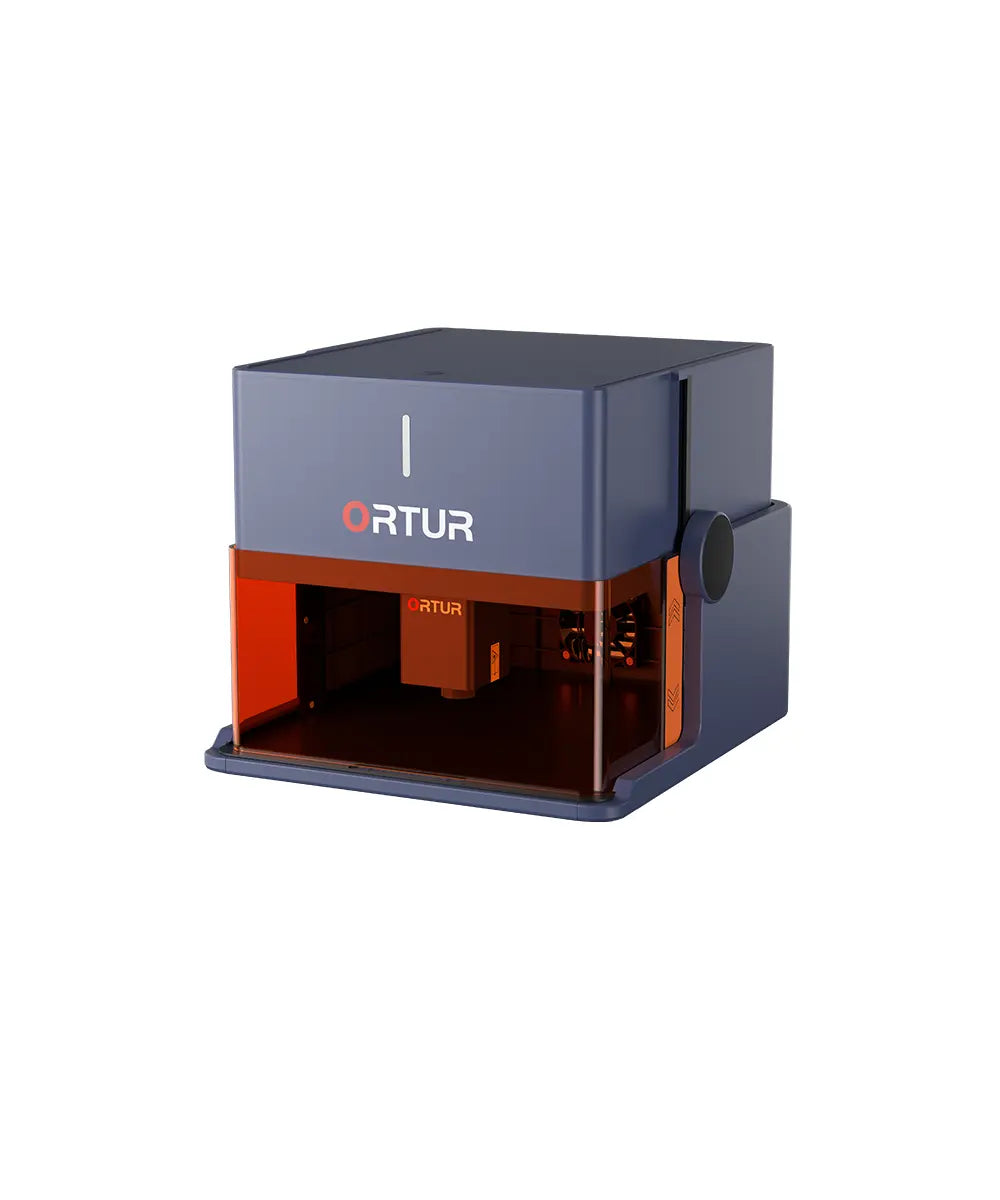

What is the working area of R1?

Ortur R1 has a maximum engraving area of 100mm*100mm with the 5 watts laser module and 100mm*80mm with the 1.3 watts IR laser module.

There are two tpyes of laser modules, which one should I choose, 1.3W(1064nm) or 5W?

It depends on what material you intend to engrave with Ortur R1. The 5W laser module is suitable for non-metal materials, while the 1.3W IR laser module is suitable for metal materials.

Can the R1's laser modules be adapted to other Ortur laser engravers? Or conversely, can other types of laser modules be adapted to the R1?

The 1.3W infrared laser modules used in R1 and R2 are the same, but the 5W laser module used in R1 is exclusive to R1 and can't be adapted to use in other machines.

Are there any Ortur accessories compatible with the R1?

Currently, none.

What is the working area of R2?

Ortur R2 has a maximum engraving area of 300mm*210mm with the 1.3 watts IR or 10 watts laser modules, and 300mm*190mm with the 20 watts laser module.

There are three tpyes of models, which one should I choose, 1.3W(1064nm), 10W or 20W?

1.3W(1064nm) can expand more types of materials like metals, metal oxides, coated metals, alloys and plastics. 10W is the best choice for fine engraving and versatile for light cutting. 20W is suitable for both engraving and cutting projects.

Can the R2's laser modules be adapted to other Ortur laser engravers? Or conversely, can other types of laser modules be adapted to the R2?

The 10W LU3-10A laser module on the R2 is only adapted to R2, but the 1.3W IR LR4-1A laser module is compatible with other Ortur laser engravers like Ortur R1, F10, OLM3, OLM2 PRO S2, OLM3 LE, OLM H10 and OLM2S2.

How does flame detection work? What does it do? Under what circumstances is it triggered?

The R2 has 5 flame recognition points that will recognize flames that have a continuous rise in temperature in addition to the laser beam when the machine is performing a cutting operation. If it is detected by more than 3 detection points at the same time, it will automatically trigger the power-off protection.

What accessories are compatible with the R2?

The R2 can be used with Ortur YRC1.0, YRR3.0, YRR2.0, OUR1.0, OSP1.0 and OAP1.0.

What's the function of Triangular Blade in the R2 box?

How do l assemble and set up the Ortur R2 for the first time?

How do I properly use the Ortur R2 software for my laser engraving projects?

Please refer to the R2 Lightburn tutorial and LaserGRBL tutorial.

Where can I find the tutorials of R2?

Please refer to Tutorials for Ortur R2.

What is the engraving area of H20?

Copy of The H20 has a maximum engraving area of 420 x 300mm with the 10 or 20 watts laser modules, 410 x 275mm with the 40 watts laser module and 420 x 275mm with the 1064nm infrared laser module.

Is H20 a auto focus laser engraver?

Copy of The H20's 40W laser module is autofocused, while the remaining 2W, 10W and 20W laser modules require manual focusing.

Is this a fully enclosed Class 1 laser? What's the differences between it and other laser engravers of the same type?

Copy of Yes, it is a Class 1 laser. And what makes the H20 unique compared to other products is that it is like Legos and can be used in three layers. For example, if only the middle body layer is used, it is a box opener. If you use a combination of the upper and middle layers, you get a laser machine with a large engraving height and laser protection. If you use all three layers together, you get a laser machine that is fully enclosed, has a powerful exhaust function, and has its own lifting function

Can the H20's laser modules be adapted to other Ortur laser engravers? Or conversely, can other types of laser modules be adapted to the H20?

Copy of All laser modules on the H20 are customized and can't be adapted to other Ortur laser engravers. Other types of laser modules can't be adapted to the H20, either.

What accessories are compatible with the H20?

Copy of The H20 can be used with Ortur YRR3.0, YRC1.0, OSP1.0 and OAP1.0.

How do l assemble and set up the Ortur H20 for the first time?

Copy of Click to watch the video

How do I properly use the Ortur H20 software for my laser engraving projects?

Copy of Please refer to the H20 Lightburn tutorial and LaserGRBL tutorial.

How can I use H20's camera?

Copy of Please refer to the following two tutorials:

Ortur H20 Camera Lens Calibration Tutorial for Lightburn and Ortur H20 Visual Positioning Tutorials for ORTUR.

How to connect the external air pump to the H20?

Copy of Click to watch the video

What can the H20's 1064nm laser module do? Is it a must-have?

Where can I find the tutorials of H20?

Copy of Please refer to Tutorials for Ortur H20.

How do l assemble and set up Ortur Laser Master 3 for the first time?

What accessories are compatible with Ortur Laser Master 3?

Ortur Laser Master 3 can be used with LEP1.0, OAP1.0, YRC1.0, YRR3.0, YRR2.0, FFT1.0, ETK2.0, Ortur Enclosure 2.0, Ortur Adjuster and Ortur Smoke Purifier 1.0. (Almost compatible with all accessories)

There are three tpyes of models, which one should I choose, 10W, 20W or 40W?

10W is the best choice for fine engraving and versatile for light cutting. 20W is suitable for both engraving and cutting projects. 40W is ideal for thick cutting projects and increase working efficiency.

Can Ortur Laser Master 3 truly engrave at the speed of 20,000mm/min?

Yes, it can! And this has been achieved by using 4 main changes in design.Firstly, the Ortur Laser Master 3 was redesigned to make its mechanical structure center of gravity as low as possible. Ultimately, there is a substantial reduction in the harmonic vibrations of the frame.Secondly, the LU2-10A 10W laser module that powers the Ortur Laser Master 3 is extremely light. Weighing only 235 grams, it maintains high power output and cooling performance.Thirdly, the Ortur Laser Master 3 motherboard and firmware employ G-code streaming optimization, allowing data transfers to break the previous limit of 6,000mm/min.Fourthly, TMC2209 stepper driver chips are used on the Ortur Laser Master 3. These high performance drivers allow for high torque, silent operation and no switching homing.

What are the differences between Ortur Laser Master 3 and Ortur Laser Master 3 LE?

There are 3 main differences.

1. The maximum speed of Ortur Laser Master 3 is 20,000mm/min while the maximum speed of Ortur Laser Master 3 LE is 15,000mm/min.

2. Ortur Laser Master 3 has 8 safety functions while Ortur Laser Master 3 LE has only 6 safety functions excluding emergency buttons, and a child lock.

3. The engraving area of Ortur Laser Master 3 can be extended to 400mm*850mm with ETK2.0 but Ortur Laser Master 3 LE can't be extended.

Why does Ortur Laser Master 3 keep flashing in red and green or sometimes in yellow and white with intermittent beeping?

Ortur Laser Master 3 does not recognize the SD card, please make sure that the SD card is inserted normally. If it still flashes after the SD card has been inserted, please reinsert the SD card or restart the machine.(Note: The machine must be inserted into the SD card before use, generally in no special circumstances, do not remove the SD card, so as not to cause the machine lighting display abnormalities and some engraving abnormalities)

How to adjust the belt tension?

X-axis Belt Adjustment Instruction: https://youtu.be/Qetc1j6izg0?si=bd1VPN0-hSAoESKr

Y-axis Belt Adjustment Instruction: https://youtu.be/7kBa45u-vWw?si=pztHwAxVDmf9vqfI

How to update Ortur Laser Master 3's firmware?

Please download the latest firmware from https://ortur.net/pages/support-olm3 and follow this tutorial https://youtu.be/B3SiPXteRvA?si=5y6aRFtyr-yRw2R7. (The firmware is the operating system that resides on your machine's motherboard and controls all operations and interactions between the motherboard and the host computer. In some circumstances, a firmware update may be required to improve the Ortur machine's performance or to correct problems found. In some less common situations, a firmware upgrade may be required to correct problems caused by user's incorrect operations.)

How to replace the motherboard of OLM3?

Where can I find the tutorials of OLM3?

Please refer to Tutorials for OLM3 10W, Tutorials for OLM3 20W and Tutorials for OLM3 40W.

What is the engraving area of F20?

It's 400mm*3000mm (118''×15.75'' ).

Is Ortur F10 compatible with other laser modules?

Yes. All Ortur laser modules are compatible with Ortur F10, e.g. LR4-1A, LR4-2B, LU3-40A, LU3-20A, LU2-10A, LU2-4 SF, etc.

Click to watch the video

What is the maximum thickness of material supported by Ortur F10?

The maximum thickness of plywood supported is 15mm.

How do I ensure the material processing accuracy?

It is best to engrave or cut from flat materials that are free of warped edges, arched parts, or twists. (Please note that soft and flexible materials are easily distorted and may not be accurately conveyed. For thinner soft and flexible materials, it is recommended to use adhesive tape on the backside of the material before processing to prevent shifting.)

How to clean and maintain Ortur F10?

You can use a brush to clean some parts, such as the dule pressure rollers or the light connection plate. It is recommended to clean Ortur F10 by using tissues moistened with alcohol after using every time. If left uncleaned for a long time, the residual stains may become difficult to clean.

Where can I find the tutorials of F10?

Please refer to Tutorials for Ortur F10.

Why the H10 20W is suitable for beginners?

✅H10 20W comes in pre-assembled package, no need to spend time installing.

✅Work with Smart APP to make the operation easier.

✅Free air assist included at no extra cost.

How to install H10 for the first time?

Can l change other laser modules on the H10?

Yes, H10 can be directly adapted to LR4-1A, LR4-2B, LU3-20A/B, LU2-10A, LU2-4SF/LF, LU2-2.

Which accessories are recommended for H10?

✅The Air Assist Set and Engraving Platform are must-haves. Air Assist Set blows away the dust on the laser head, making your projects clean without burn marks and protect the lenses. Processing on Engraving Platform avoids laser shooting at your desk.

✅90% of users also order YRC1.0 for cylindrical processing, like tumbler , Christmas ball and ring engraving.

✅The H10 exclusive raiser (ORP1.0) is an essential assistant to the Y-Series rollers, and it can also be stacked indefinitely to engrave super-tall objects.

✅For indoor use, using the Enclosure 2.0 with a smoke purifier will keep your indoor air clean.

What is the difference between the LU3-20A and H10's LU3-20B?

LU3-20A packed with cos technology, which has the better cutting capacity in current Ortur laser modules.LU3-20B assembled with optical compression technology, which can handle the majority of thick materialsPlease refer to Product Comparisons to learn more details.

How do I choose between two 20W laser machines, the H10 and the OLM3?

The H10 is a pre-assembled machine that you don't need to spend much time installing the machine, making it more friendly to novices.The OLM3 has the most complete range of accessories and a wide range of scenarios, which can be adapted to a wide variety of engraving needs.For the specific parameters of the two machines, please refer to Product Comparisons.

Where can I find the tutorials of H10?

Please refer to Tutorials for Ortur H10

How to assemble OLM2 Pro S2?

Which laser module should I choose if I want to upgrade my OLM2 Pro S2?

20W LU3-20A and 1.3W IR LR4-1A Laser Modules are both good choices.

What are the main differences between OLM2 Pro S2 and OLM2 S2?

There are 3 main differences.

1. The maximum speed of OLM2 Pro S2 is 15,000mm/min while the maximum speed of OLM2 S2 is 5,000mm/min.

2. OLM2 Pro S2 has 7 safety functions while OLM2 S2 has only 5 safety functions excluding flame detector and emergency stop button.

3. The engraving area of OLM2 Pro S2 is a little bit larger than OLM2 S2.

What accessories are compatible with OLM2 Pro S2?

OLM2 Pro S2 can be used with LEP1.0, OAP1.0, YRC1.0, YRR3.0, YRR2.0, OUR1.0, ETK1.0, Ortur Metal Enclosure, Ortur Enclosure 2.0, Ortur Adjuster and Ortur Smoke Purifier 1.0.

How to replace the motherboard of OLM2 Pro S2?

Where can I find the tutorials of OLM2 Pro S2?

Please refer to Tutorials for OLM2 Pro S2.

How to assemble OLM2 S2?

Can I extend the engraving area of OLM2 S2?

Yes. Its engraving area can be extended to 390mm*800mm by using Ortur extension kit.

What's the difference between LU2-4 LF and LU2-4 SF?

LU2-4 LF is more suitable for cutting and LU2-4 SF is more suitable for engraving.

Can OLM2 S2 be operated by a phone?

No, this machine does not support connection with phones. It can only be operated by computer.

Where can I find the tutorials of OLM2 S2?

Please refer to Tutorials for OLM2 S2.

Which laser module should I choose, 10W, 20W or 40W if I want to upgrade my engraving machine?

10W is the best choice for fine engraving and versatile for light cutting. 20W is suitable for both engraving and cutting projects. 40W is ideal for thick cutting projects and increase working efficiency. We also have 1.3W and 2W infrared laser modules if you want to engrving metals or plastics. For more details, please refer to Product Comparisons

How long is the lifespan of the laser module?

It is about 10,000 hours. The power may decrease by roughly 15% as the hours of use increase. Please note that you have to clean the lenses regularly for dirty lenses can cause you to lose the laser power.

Are all H20's laser modules autofocused?

The H20's 40W laser module is autofocused, while the remaining 2W, 10W and 20W laser modules require manual focusing.

Can the H20's laser modules be adapted to other Ortur laser engravers?

All laser modules on the H20 are customized and can't be adapted to other Ortur laser engravers.

Can the R2's laser modules be adapted to other Ortur laser engravers?

The 10W LU3-10A laser module on the R2 is only adapted to R2, but the 1.3W IR LR4-1A laser module is compatible with other Ortur laser engravers like Ortur R1, F10, OLM3, OLM2 PRO S2, OLM3 LE, OLM H10 and OLM2S2.

What materials can be engraved by the infrared laser module?

All kinds of metals, leather, opaque plastics, dark-coloured opaque plastics, stone, glass(marking paper required), etc.

Can LR4-1A and LR4-2B 1064nm Infrared Laser Modules be used for cutting?

No, they can only be used for engraving.

What machines and accessories are compatible with the infrared laser module LR4-2B?

It is compatible with OLM3, OLM3 LE, H10 and F10. And it can be used with the YRC 1.0 to engrave rings, cups, etc

What machines and accessories are compatible with the infrared laser module LR4-1A?

It is compatible with Ortur R1, F10, OLM3, OLM2 PRO S2, OLM3 LE, OLM H10 and OLM2S2. And it can be used with the YRC 1.0 to engrave rings, cups, etc

Can I switch the power during using the 40W LU3-40A Laser Module?

It is not recommended to switch the power when using it midway.

Which engraving machine can the 40W LU3-40A Laser Module be used with?

OLM3, OLM3 LE and F10 can be connected via OUC2.0.

What is the principle of switching 20W power to 4ow power (LU3-40A Laser Module)?

It is realized by controlling the switches, 4 diodes emit light in 20W mode, and all 8 diodesemit light in 40W mode.

How to clean the lens laser module?

What's the difference between YRR2.0, YRR3.0, YRC1.0?

Both YRR2.0 and YRR3.0 can engrave cylindrical objects, but YRR2.0 has a length limitation while YRR3.0 supports longer cylindrical objects. yrrc1.0 has multiple engraving modes and is capable of engraving cylindrical objects as well as irregularities such as rings, baseballs, cups with handles, etc.

How Ortur Laser Master 3 works with the Rotary Roller Series

There is no need to remove the connection of the Y-axis motor to insert the YRR 2.0, YRR 3.0, YRC 1.0. And with a single-stroke switch, you can make a conversion between the Rotary Roller and the Y-axis motor.

Click to watch the video

What's the function of Ortur Laser Engraving Platform, is it a must-have?

Ortur Laser Engraving Platform can provide suspension support, smoke conduction and fixation for the engraving, effectively avoiding the yellow engraving objects caused by the smoke accumulation when using ordinary honeycomb boards.

How to clean the Laser Engraving Platform?

It can be cleaned by detergent.

What laser modules is the Z-Height Adjuster compatible with?

It is compatible with all Ortur laser modules except LR4-2B, H20's laser modules and R2's laser modules.

What material is the Ortur Enclosure 2.0 made of? What are the machines it can be adapted to?

It is made of fireproof cloth and fireproof plastic and can be adapted to all Ortur & Aufero Laser Engravers except F10, H20 and R2.

What is the Air Assist? Is it the same as the Air Pump?

Laser modules like LU2-4 LF, LU2-10A, LU3-20A/B, LU3-40A have Air Assist. The Air Pump is a recommended accessory for use with Air Assist during cutting, it can blow away the oil smoke and residue produced by the laser engraving machine. It helps make the cutting effect better, and prevent the appearance of the black edge. So the Air Pump is highly recommended when cutting.

How can I choose the right feet for rising up my machine if I want to use the Rotary Roller Series?

There are three tyes of feet for rising up the machine. FFT1.0 is only for Ortur Laser Master 3, ORP1.0 is only for Ortur Laser Master H10, and OUR1.0 is suitable for all Ortur and Aufero machines.

How to prevent the smoke when engrving or cutting?

Ortur Enclosure 2.0 is a good choice to prevent the smoke. And it will be even have a better effect if it uses with Ortur Smoke Purifier 1.0.

How can I extend the engraving area?

Where can l find replacement parts?

What materials can I process with the laser engraving and cutting machine?

The laser engraving and cutting machine is suitable for create millions of DIY projects based on hundreds of materials including plywood, MDF, metal, leather, glass, paper, dark acrylic, fabric, plastic and more.

What speed and power setting should I use for different materials?

Please refer to Materials Reference.

Does Ortur laser engraving machine support engrave on a cylinder?

Absolutely! You can use the laser engraving machine with Ortur YRC1.0, YRR3.0 or YRR2.0 to engrave objects like mugs, cups, tumblers, baseball bats and more.

Click to watch the video

Can Ortur laser engraving machine engrave metal and stainless steel?

Blue lasers can engrave stainless steel, coated metals and oxidized metals but can't engrave pure metal. If you want to engrave pure metals, we will recommend infrared lasers like Ortur 2W IR LR4-2B and 1.3W IR LR4-1A.

How to use a laser to engrave or cut transparent acrylic?

Our lasers can engrave and cut color acrylic but can't cut transparent acrylic. In fact, any diode lasers can't cut transparent acrylic. If you want to engrave transparent acrylic, it needs to be wrapped with black marking paper to avoid reflections.

Can a laser engrave glass?

Yes, our laser can engrave glass. But you have to use the black marking paper or paint the glass black to avoid reflections.

What is the thickest piece of material that an engraver can cut?

Please refer to Materials Reference.

Do I have to use engraving machine with software?

Yes, LaserGRBL (Win XP, Win7, Win8, Win10, Win11) and Lightburn (Mac OS, Linux, Win XP, Win7, Win8, Win10,Win11) is recommended. Smart Laser Engraving Machines like Ortur R1, Ortur R2, H20, F10, Laser Master 3, Laser Master 3 LE and Laser Master H10 support the use of our self-developed APP ORTUR.

Where to download the software?

Please click Quick Start Guide to download.

Do l need to pay for software?

LaserGRBL and our self-developed APP ORTUR are free, Lightburn needs to be paid by youself.

What is the difference between software Lightburn and LaserGRBL?

What payment methods do you accept?

We accept PayPal, credit cards, and bank transfer.

In addition to the USD, can l pay in other currencies?

Our default currency is set to USD, customers paying in other currencies will be automatically converted according to the exchange rate.

How long does the shipping take?

We will ship from US, CZ, CN warehouse, the delivery time will be depended on your location and stock availbility. Please refer to our shipping policy for more details.

Do l have to pay extra shipping cost, taxes or tariffs?

For most countries, we provide free shipping. But for some remote areas, including islands, etc., free shipping is not provided. Buyers need to pay part of the shipping fee.

As for the taxes and tarriffs, Ortur will pay all the relative tariff costs. our customers do not need to pay any tariff fees.

For more details, please refer to our Shipping Policy.

Do you have home delivery service?

Currently, we do not offer home delivery service.

What should l do if i haven't receive my order for a long time?

1. Click Track Your Order to check the status.

2. Contact Support@ortur.net for more details.

What's your return policy?

You have 30 days to return an item from the day you received it. To be eligible for a return, your item must be in the same condition as when you received it, unworn or unused, with tags, and in its original packaging. To start a return, please contact us at Support@ortur.net and send us pictures of the product's condition. If your return is accepted, we'll send you a return shipping address and instructions on how to send the package back to us. Please note that we won't accept items sent back to us without a return request.

For more details, please refer to our Refund Policy.

Can l cancel or modify my order?

Yes, you can contact us at Support@ortur.net as soon as possible, we will do our best to accommodate your request.

How long is the warranty period? Can l extend the warranty period?

All products sold on our website come with a one-year technical warranty for non-human causes. We have no extended warranty for the time being.

Where do l get warranty if there’s any issues with my laser?

If you face any difficulties while using our products, feel free to contact us at Support@ortur.net. If possible, providing photos or a video of any malfunctions would greatly assist us in resolving it promptly.

Free Shipping

Free shipping for 99% of regions,partially charged

One Year Warranty

Professional technical support and service

30 Days Return

Accept the return of the original package