What is Air Assist on a Laser Cutter &

Why Should You Care

This article walks you through the question of what is air assist on a laser and why it is extremely important to be incorporated into a laser cutter and engraver, along with our recommendations.

- Cooling for Burning Surfaces

- What is Air Assist on a Laser Cutter?

- How Air Assist Works?

- Conclusion

Cooling for Burning Surfaces

If you were searching with the keywords how to make graphic tees with your laser cutter and engraver, then we suspect that you are one of those individuals always looking to have personalized clothes for themselves. Tees are virtually available in infinite designs, but having your own tee with graphics according to your personality is a different game. There are many ways to do it; a few of them are explained below to give you an idea of which one suits your needs:

What is Air Assist on a Laser Cutter?

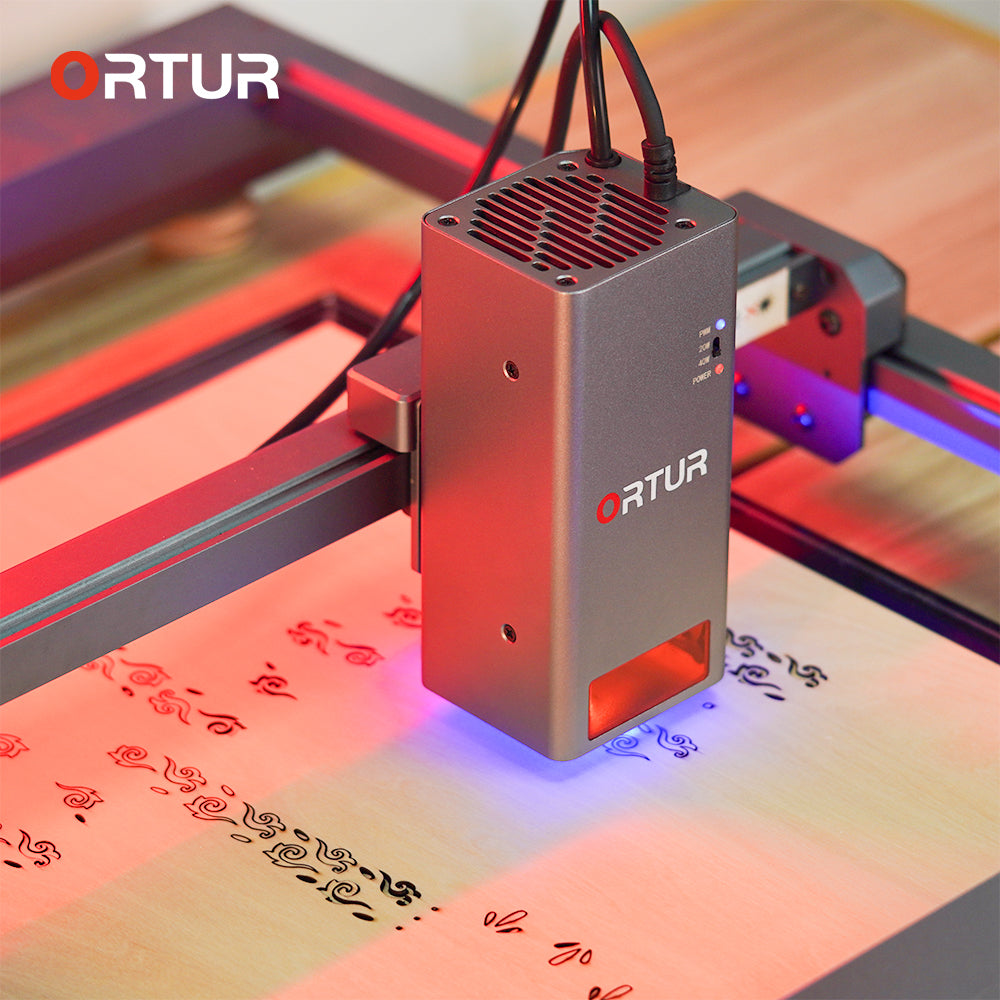

This is a special feature found on laser cutters and engravers that uses water coolants and compressed air and blows it onto the surface area where the engraving process is being carried out. This feature is significant in many ways: cutting quality is improved due to the removal of any debris that can clog up the cutting area and cause inaccuracies in the engraving or cutting results.

Moreover, it also deals with fumes and smoke at the cutting spot, which avoids any hazardous situations like catching fire or filling your workspace with smoke. Since there is high-speed air flowing on the surface, it also reduces the buildup of chemical residue on your engraved surface after the surface is burned. You also get an air stream cooling down the entire surface being engraved, which increases the durability of the lens of the laser hardware and also makes the entire operation much faster.

So, in short, this system is extremely significant for a laser cutter and engraving system, and if you are planning to invest in new hardware, this feature is a must-have since it has a major impact on the final results of your engraving. For this, the Ortur LM3 laser engraver is one of the few that has a state-of-the-art integrated air assist installed on the hardware which performs exceptionally well. But the question here is, how do such systems work?

How Air Assist Works?

So now you know what is air assist on a laser, its working needs to be explored as well. Such systems come with an air compressor unit along with a tubing carrying coolants. The theory behind the working of air assist systems is that the laser engraving operation is an exothermic reaction on the surface on which you are working and this reaction process releases energy that is given out as light or heat. When nitrogen, oxygen, or pressurized air is applied it assists in the transfer of heat besides the beam. In air assist systems, air is used to do the same job.

The air from the compressor in an air assist system is circulated over the material at all times that your laser is engaged in cutting or engraving. The end airflow constantly removes heat and establishes a buffer between the laser beam and your material to ensure that the laser does not overheat.

A few years ago, the most popular gas for laser engraving along with air assistance was oxygen and later nitrogen in industrial sectors. For domestic uses, the compressed air works perfectly fine and is free to use as compared to the other two pure gases. Most laser cutters use air as cooling gas for their compressors Ortur LM3 uses a 50L compressor pumping air through an air tube right into the laser module where it is further combined with dual fans and efficiency-guided airflow blinds, giving the laser module all the safety and “cool” conditions, it needs for best possible cutting and engraving results.

Conclusion

While we talked in depth about the question what is air assist on a laser and how it works, it is worth mentioning that such systems are nowadays becoming a norm in the laser cutting industry. So, if your laser hardware lacks it, we highly recommend making a switch to a system integrated with such safety systems.

Keep in Touch with Ortur

Related Articles